Product Features :

HIGH PRECISION STABILITY AND RELIABILITY

High steel alloy casting frame structure (with the most suitable for the frame designed by computer anal-ysis), processed by the internal stress elimination pro-cess, and further improving the high rigidity frame,achieving low noise and low vibration, and improving service life of the die.

Standard configuration :

■ Electric model height adjustment .

■ Die height display precision 0.01mm .

■ Inching positioning device .

■ The computer can memorize data of 30 sets of mold .

■ Three groups of batch control .

■ Two groups of feed error detection .

■ Linked/single action, with 0° and 90° positioning function .

■ Host forward/reverse device .

■ Hydraulic slide lock device .

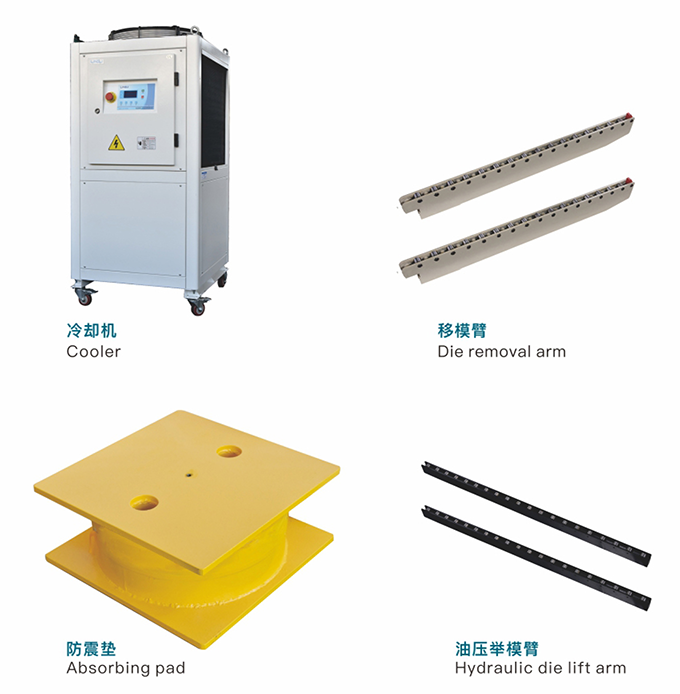

■ Lubricating oil cooling cycle machine .

■ Italian OMPI integrated clutch brake .

■ Independent electric control cabinet .

■ Tooling box .

■ Work area light .

■ Main motor frequency converting control .

Optional configuration :

■ Bottom dead center precision detector .

■ Quick die clampers .

■ Hydraulic die lifting device .

■ High speed feeder .

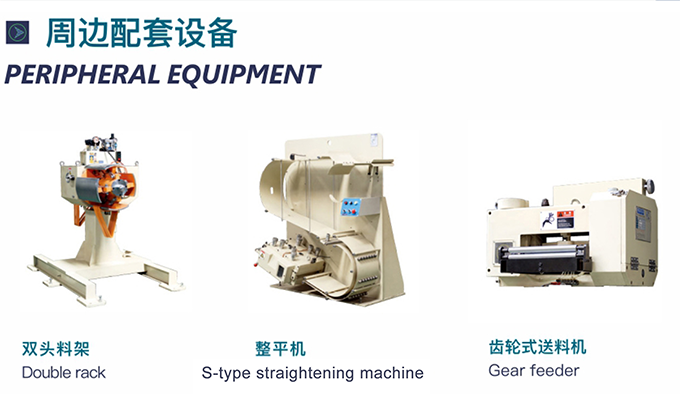

■ Double head decoiler .

■ Leveling machine .

■ Hydraulic anti-viberatioin cushion .

■ Punching controller .

■ Front and rear safety protect door.

* Provide Customized Personalized Service

|

XPJ- 60ton ~200ton |

|

Model |

Unit |

XPJ-60 |

XPJ-80 | XPJ-125 | XPJ-150 | XPJ-200 |

| Tonnage | Ton | 60 | 80 | 125 | 150 | 200 |

| Travel | mm | 30 | 30 | 30 | 30 | 30 |

| Number of stokes per minute | s.p.m | 200-800 | 200-700 | 150-700 | 150- 600 | 150-600 |

| Lower table size | mm | 950x650 | 1100x750 | 1200x850 | 1400x850 | 1700x950 |

| Blanking hole | mm | 700x125 | 800x150 | 1000x200 | 1200x200 | 1300x250 |

| Sliding block area | mm | 950x420 | 1100x500 | 1200x600 | 1400x600 | 1700x700 |

| Die height adjustment stroke | mm | 300-350 | 330-380 | 360-410 | 360- 410 | 370-420 |

| Die height adjustment motor | kw | 0.4 | 0.75 | 0.75 | 0.75 | 1.5 |

| Feeding line height | mm | 160 | 175±50 | 195±50 | 195±50 | 200±50 |

| Main motor | kw | 19 | 22 | 30 | 37 | 45 |

|

XPJ- 220ton~450 ton |

|

Model |

Unit |

XPJ-220 | XPJ-300 | XPJ-400 | XPJ-150 | XPJ-450 |

| Tonnage | Ton | 220 | 300 | 350 | 400 | 450 |

| Travel | mm | 30 | 30 | 30 | 30-50 | 30-50 |

| Number of stokes per minute | s.p.m | 150-600 | 150- 400 | 150- 350 | 150-350 | 150-300 |

| Lower table size | mm | 1900x1000 | 2200x1000 | 2400x1000 | 2800x1200 | 3000x1200 |

| Blanking hole | mm | 1400x300 | 2000x300 | 2200x300 | 2200x400 | 2500x400 |

| Sliding block area | mm | 1900x750 | 2200x900 | 2400x900 | 2800x1100 | 3000x1100 |

| Die height adjustment stroke | mm | 370-420 | 400 -450 | 400- 450 | 420- 480 | 450-500 |

| Die height adjustment motor | kw | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 |

| Feeding line height | mm | 200±50 | 210±50 | 210±50 | 220±50 | 270±50 |

| Main motor | kw | 45 | 55 | 55 | 75 | 75 |