Product Features :

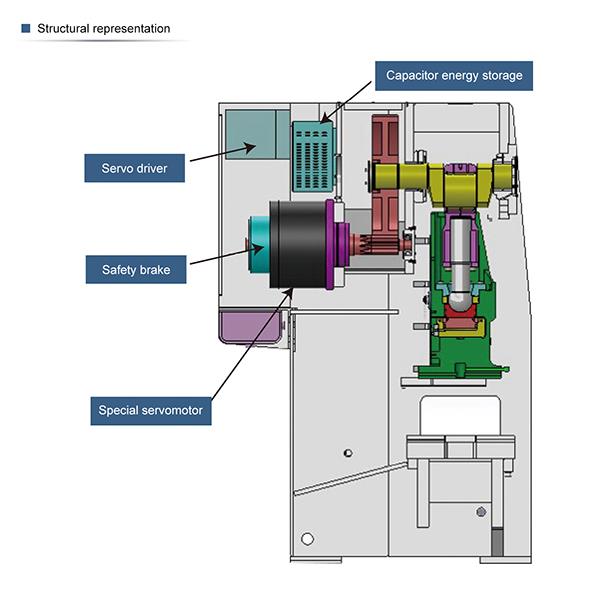

■ High torque, low RPM servo-motor.

■ Servo drive and servo controller.

■ ECO servo press energy management system .

■ Manual step adjustment of mold .

■ Mechanical safety brake .

■ Hydraulic overload protection .

■ Full re-circulating oil lubrication system .

■ CNC control with colorful HMI .

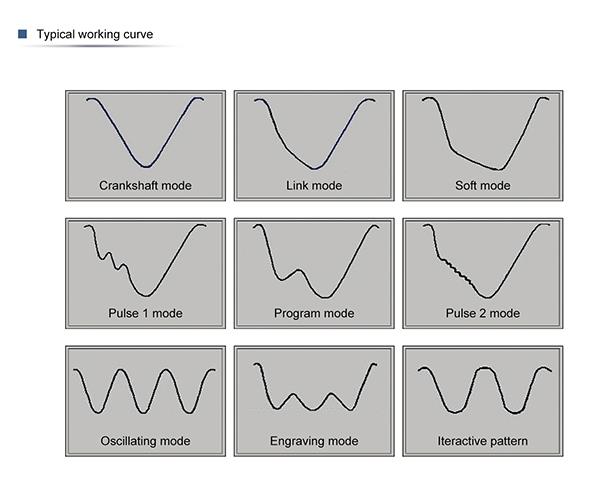

■ The slider running modes can be programmed flexibly according to the technology requirements .

■ Working area safety protection, front equip with light curtains, side with guardrails .

Standard configuration :

■ Hydraulic anti-stuck device.

■ Die height value displayed accurately to 0.01.

■ Slider adjustment electrically.

■ Pre-set function of upper dead position .

■ Forced lubrication system(thin oil).

■ Control panel.

■ T-type operating panel .

■ Servo drive.

■ Various controllers of punching process.

■ Servo controller.

■ Power source monitor.

■ Programmable controller.

■ Human- computer interface.

■ Four sets of spare CAMS.

■ Output count.

■ Three groups of pre-sets,six digital display.

■ 99 mould Data storage for 99 sets of mould.

■ Mold light in front of the machine.

■ Emergency stop button.

■ Blowing material interface.

Optional configuration :

■ Die quick change system (Die lifter , die clampers )

■ Die cushion

■ Micro-mioving wheel

■ Die protection, 3 channels

■ Mould protection, 7 channels

■ Automatic air supply

■ Equip with rear safety cover door

■ Independent button station

■ Work light

■ Mould safety plug

■ Load monitor and analysis software

■ Anti-viberation pad

■ Anchor bolts

■ Running mode setting software

■ Tool socket 220V

■ Slider automatic adjustment

■ Electric interface for muiti -axis robot

■ Select switch for pre-set stop position

■ Normal pneumatic pressure for knocking out material

* Provide Customized Personalized Service

|

Name |

Unit |

X1S-80 |

X1S-110 |

X1S-160 |

X1S-200 |

|

|

Capacity |

Ton |

80 |

110 |

160 |

200 |

|

|

Working energy |

J |

4000 |

4600 |

7900 |

13100 |

|

|

Slider Stroke |

Full stroke |

mm |

160 |

180 |

200 |

220 |

|

Fwd./Rev./Motion |

mm |

60/100/130 |

70/110/150 |

80/120/160 |

90/140/180 |

|

|

Number of continous strokes per minute |

At full |

SPM |

80 |

70 |

60 |

50 |

|

Fwd./Rev./Motion |

SPM |

118/96/82 |

114/93/76 |

100/82/68 |

81/67/57 |

|

|

Die height |

mm |

320 |

350 |

400 |

450 |

|

|

Slide adjustment |

mm |

80 |

90 |

100 |

110 |

|

|

Slide area |

L-R |

mm |

700 |

800 |

900 |

1000 |

|

F-B |

mm |

460 |

520 |

580 |

650 |

|

|

Bolster area |

L-R |

mm |

900 |

1000 |

1150 |

1250 |

|

F-B |

mm |

600 |

680 |

760 |

840 |

|

|

Thickness |

mm |

140 |

155 |

165 |

180 |

|

|

Max.upper die weight |

kG |

183 |

218 |

225 |

430 |

|

|

Main Motor (AC Servo) |

kW |

35 |

40 |

50 |

65 |

|

|

Power supply capacity |

kVA |

16 |

22 |

30 |

32 |

|

|

Required air pressure |

Mpa |

0.5 |

0.5 |

0.5 |

0.5 |

|

|

Foundation bolt position |

mm |

1220×1200 |

1344×1310 |

1525×1590 |

1360 ×2020 |

|

|

Worktable height |

mm |

900 |

900 |

900 |

1000 |

|

|

Side opening size |

L-R |

mm |

400 |

500 |

560 |

620 |

|

F-B |

mm |

300 |

320 |

380 |

420 |

|

|

Height |

mm |

2180 |

3075 |

3285 |

3795 |

|

|

Gross Weight |

kG |

9000 |

13000 |

18000 |

21000 |

|