Product Features :

■ The machine is specially designed for sheet stamping of Plate-type Heat Exchanger according to the customized technical requirements .

■ The system is driven by servo electric pump group, which provides hydraulic power source for hydraulic press. Servo control oil pump group is used to drive, reduce power consumption and oil temperature, and reduce noise.

■ The control system is equipped with adjustment, manual and semi-automatic working modes. The working mode is selected by the transfer switch, the buttons are centrally controlled, and the two modes of forming process of fixed stoke and fixed pressure can be realized.

Configuration :

■ Servo Control system + pump

■ Piston Rods processing: (quenching + chromium plating )

■ Pressure sensor &displacement sensor

■ Photoelectrical Light Curtain Protection, 2 sets

■ Automatic Lubrication Pump

■ Mold area light

* Provide Customized Personalized Service

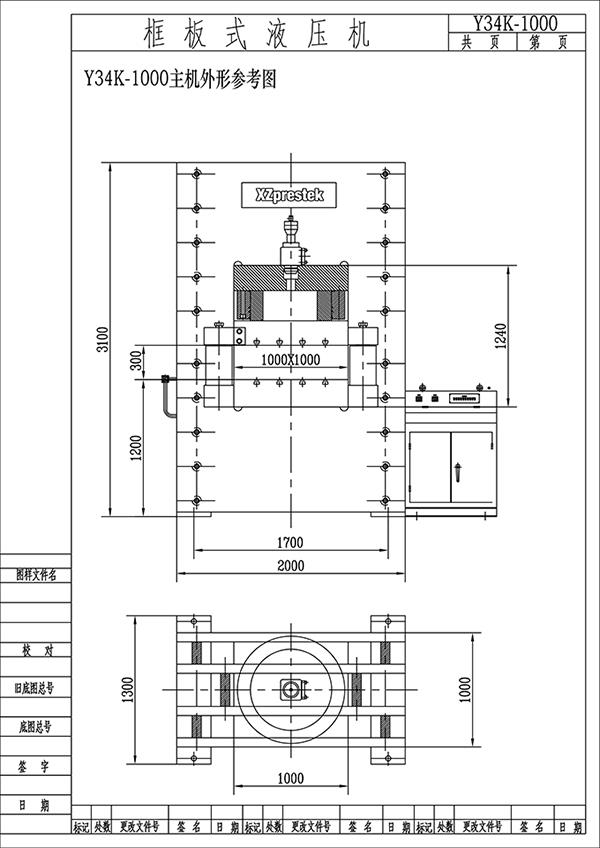

Customization 1000ton Specially for sheet stamping of Plate-type Heat

Exchanger

| No. | Item | Unit | Y34K-1000 | |

| 1 | Nominal force | kN | 10000 | |

| 2 | Slider return force | kN | about 500 | |

| 3 | Maximum working pressure of liquid | MPa | 25 | |

| 4 | Maximum distance between slider and work table | mm | 300 | |

| 5 | Maximum stroke of slider | mm | 80 | |

| 6 | Slider speed | Quick downward | mm/s | 40 |

| Pressing | mm/s | 1~2 | ||

| Return | mm/s | 40 | ||

| 7 | Effective worktable area | L- R | mm | 1000 |

| F-B | mm | 1000 | ||

| 8 | Height above ground | mm | 1200 | |

| 9 | Servo motor power | kW | 18~25 | |

| 10 | Control mode | PLC | ||

| 11 | Working medium | Antiwear hydraulic fluid | ||