Product Features :

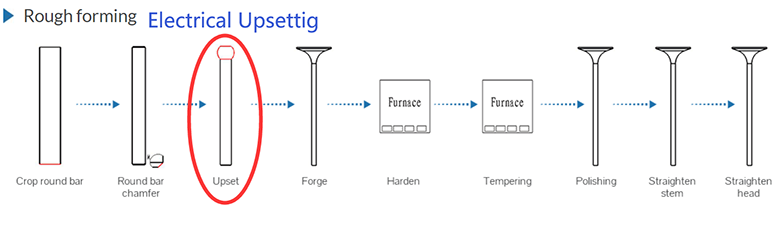

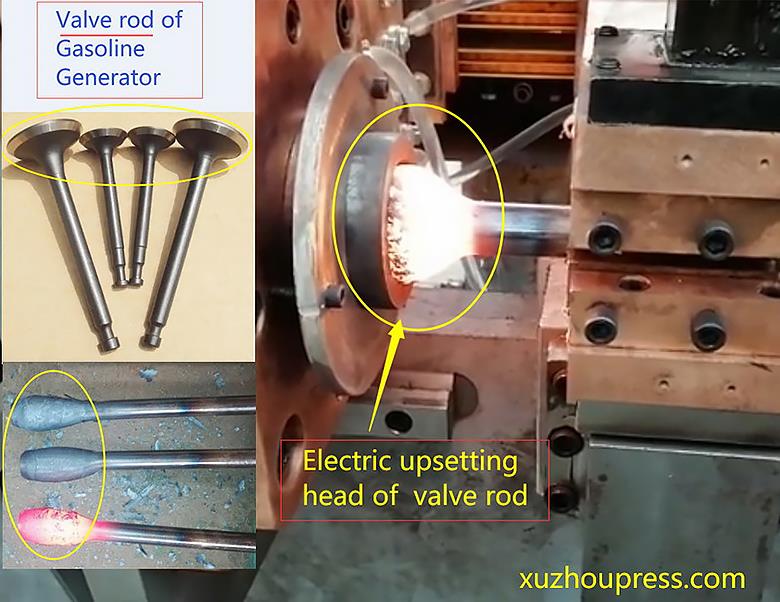

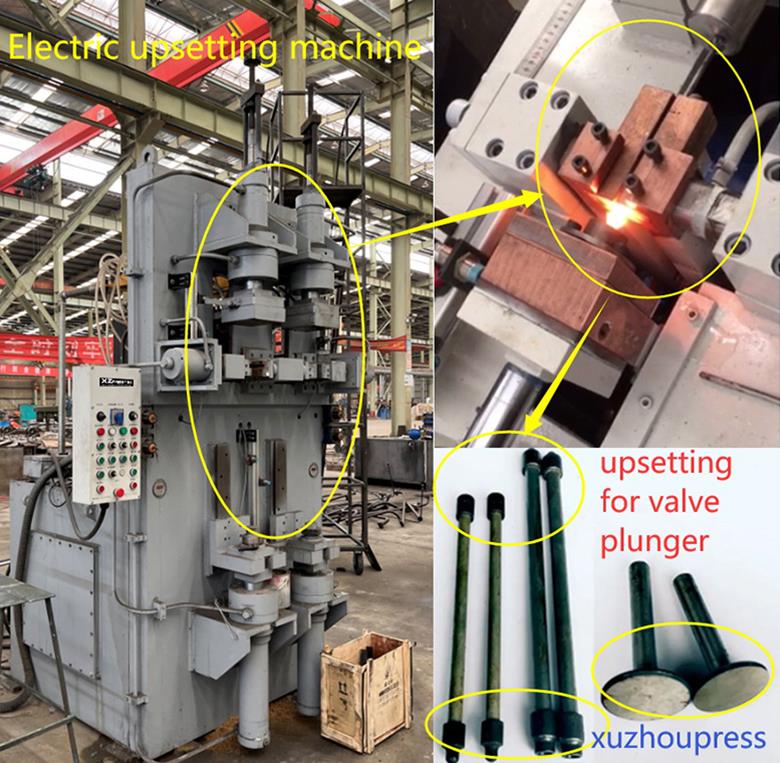

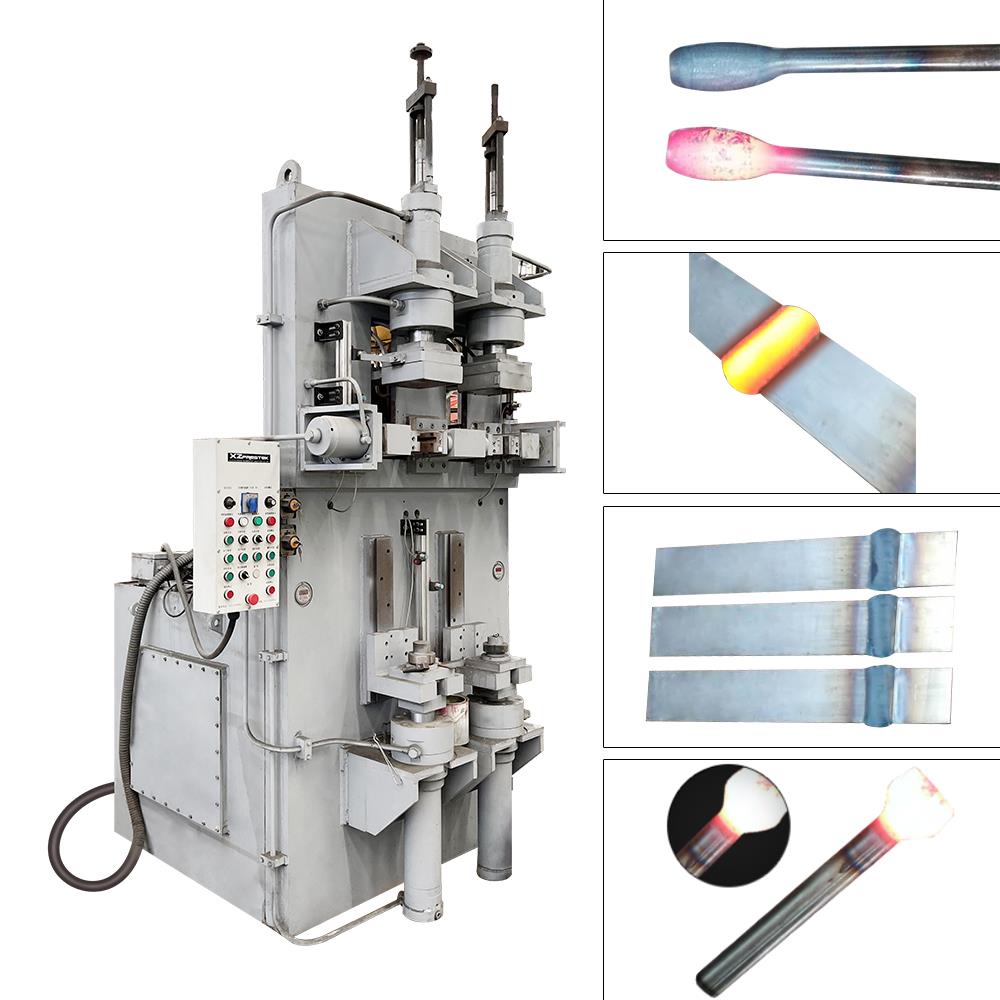

■ The electrical upsetting machine mainly completes the electric heating and upsetting process before the die forging of Engine Valve Push Rod (upsetting shape is similar to ball shape , garlic shape, cylinder type, round cake type, etc.).

■ It can also realize the heating upsetting technology of rod material, tube material and sheet material.

■ The requirements of the upsetting technology for different products can be realized by adjusting the pressure, speed, displacement and transformer output voltage of the upsetting machine.

■ The electric upsetting machine can be equipped with automatic feeding system to achieve single automation; Also can be multi - machine connection realize automatic forging production line.

* Provide Customized Personalized Service

| No | Name | Unit | EHU -2/0.5 | EHU -3/1 | EHU -4.3/1.2 | EHU -7.7/2.8 | |

| 1 | Maximum upsetting force | KN | 20 | 30 | 43 | 77 | |

| 2 | Maximum clamping force | KN | 5 | 10 | 12 | 28 | |

| 3 | Maximum stroke of upsetting rod | mm | 200 | 250 | 300 | 400 | |

| 4 | Maximum stroke of hammering block | mm | 60 | 100 | 100 | 150 | |

| 5 | Diameter of upsetting rod | mm | 5~8 | 9~12 | 13~16 | 17~25 | |

| 6 | Maximum length of upsetting rod | mm | 250 | 400 | 600 | 800 | |

| 7 | Minimum length of forging after upsetting | mm | 60 | 80 | 100 | 120 | |

| 8 |

Heating transformer |

Capacity | KVA | 30 | 50 | 70 | 120 |

| Primary voltage | V | 380 | 380 | 380 | 380 | ||

| Secondary voltage | V | 2.9 | 2.9 | 2.9 | 3.3 | ||

| 9 | Efficiency | Heating length | mm | 100 | 150 | 100 | 250 |

| Upsetting time per piece | S | 3~6 | 10~12 | 18~20 | 25~35 | ||

| 10 | Power of power system | KW | ~4 | ~5.5 | ~7.5 | ~11 | |

| 11 | Gross weight | Kg | ~2000 | ~2500 | ~3000 | ~4000 | |