Video Link:

https://www.youtube.com/watch?v=nD7gQ9Fw7D4

https://www.youtube.com/watch?v=fgtNFan-00I

https://www.youtube.com/watch?v=mRfkkLGb4nY

https://www.youtube.com/watch?v=JDgR7-KZ_2o

https://www.youtube.com/watch?v=5qBpOTpDj6I

Product Features:

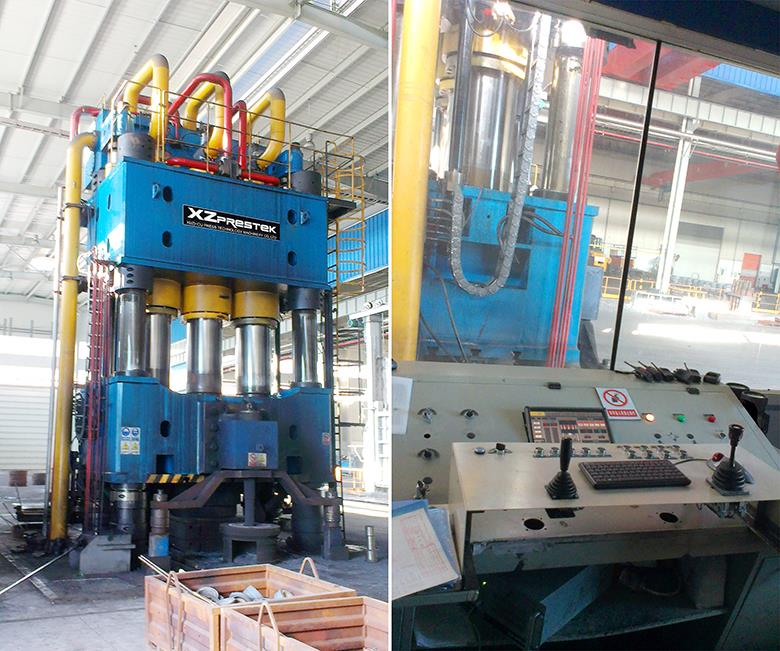

■ The host structure has two structural forms to choose :

---- Three-beam four-column structure, the operation space is spacious, the maintenance is simple, the shape is beautiful;

---- Combined H frame structure, slider guide using + six-sided adjustable mechanism, high precision, good rigidity, strong anti-biased load ability.

■ The structure of the machine body has sufficient strength and stiffness through computer 3D optimization design and finite element analysis.

■ The machine has independent hydraulic system and electrical control system. Hydraulic system adopts specially designed large flow fast forging integrated valve group, pressure classification control, can meet a variety of free forging process requirements, pressure boost, pressure relief and flexibility, improve forging efficiency and frequency,to reduce shock vibration.

■ The working pressure and working stroke can be adjusted within the parameter range according to the process needs.

■ The electrical system adopts PLC control and touch screen to display the working state of the machine. Easy to operate, sensitive and reliable action.

■ This series of press in order to meet different process requirements, the design of the corresponding devices for users to choose. And can be connect with the forging auxiliary system to achieve the mechanization and automation of forging.

Optional configuration :

■ Moving table of mold clamping device

■ Upper Anvil displacement device

■ Lower Anvil displacement device

■ Upper and lower anvil seat

■ Workpiece centering and lifting device

■ Rotary manipulator

■ Refrigerating oil cooler

■ Servo motor pump set

■ Station monitoring system

* Provide Customized Personalized Service

Y13- 800ton ~2500ton

| Item | Unit | Y13- 800 | Y13-1600 | Y13-2500 | |

| Nominal force | KN | 8000 | 16000 | 25000 | |

| Return force | KN | 750 | 1250 | 1600 | |

| Pressure classification | One | (800/1600) | (830/1660/2500) | ||

| Working position | Two | Three | Three | ||

| Maximum working pressure of liquid | Mpa | 25 | 25 | 25 | |

| Maximum stroke of the slider | mm | 1200 | 1400 | 1300 | |

| Maximum open height | mm | 2400 | 2500 | 2300 | |

| Maximum Stroke of mobile station | mm | 1800 | 2500 | 4000 | |

| Moving cylinder force | KN | 500 | 500 | 800 | |

| Moving table Moving speed | mm/s | 200 | 200 | 250 | |

| Slider travel speed | Fast down | mm/s | 350 | 350 | 350 |

| Slow down | mm/s | 50 | 50 | 50 | |

| Return | mm/s | 350 | 350 | 350 | |

| Mobile table effective size | L - R | mm | 3500 | 4000 | 5500 |

| F - B | mm | 1350 | 1200 | 1800 | |

| Column center distance | L - R | mm | 1600 | 2400 | 3250 |

| F - B | mm | 1400 | 1500 | 2000 | |

| Height of the moving platform from the ground | mm | 0 | 0 | 0 | |

| Main motor power | KW | 110X4 | 110X8 | 110X14 | |

Y13- 5000ton ~8000ton

| Item | Unit | Y13-5000 | Y13-8000 | ||

| Nominal force | KN | 50000 | 80000 | ||

| Return force | KN | 4000 | 6300 | ||

| Pressure classification | (1650/3300/5000) | (2700/5400/8000) | |||

| Working position | Three | 2700/5400/8000 | |||

| Maximum working pressure of liquid | Mpa | 25 | 26 | ||

| Maximum stroke of the slider | mm | 2500 | 2800 | ||

| Maximum open height | mm | 5200 | 5500 | ||

| Maximum Stroke of mobile station | mm | 7000 | 7000 | ||

| Moving cylinder force | KN | 2000 | 3150 | ||

| Moving table Moving speed | mm/s | 200 | 200 | ||

| Slider travel speed | Fast down | mm/s | 300 | 300 | |

| Slow down | mm/s | 60 | 50 | ||

| Return | mm/s | 300 | 3150 | ||

| Mobile table effective size | L - R | mm | 8000 | 10000 | |

| F - B | mm | 3000 | 3200 | ||

| Column center distance | L - R | mm | 3780 | 5000 | |

| F - B | mm | 3000 | 3200 | ||

| Height of the moving platform from the ground | mm | 0 | 0 | ||

| Main motor power | KW | 160X20 | 160X26 | ||