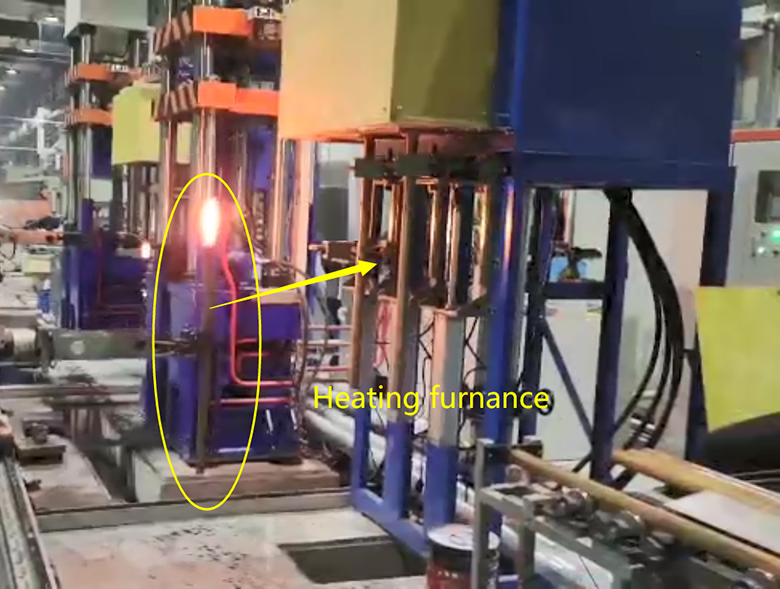

Technology Process :

According to the calculation of diameter rod, choose a suitable intermediate frequency power source with frequency furnance. The furnace body adopts three stations, and the feeding method adopts automatic air cylinder pushing mechanism;

■ Manually puts the rod into the V-shaped feeding

groove -

■ The air cylinder

pushes the rod into the induction-box for heating-

■ When the heating time met, the air cylinder automatically returns and brings back the heated rod-

■ One cycle of heating rod is completed, and then for the next cycle .

Technical Brief introduction :

■ The structure of main circuit is simple, and performance is reliable .

■ Strong starting ability .

■ Easy debugging and easy maintenance .

■ High control precision .

■ Perfect protection function, accurate and reliable action .

■ Advanced frequent startup function .

■ Advanced design of thyristor inverter central controller with perfect function .

■ Operation circuit protection system .

■ Digital intermediate frequency power supply, which popular and has been approved by the majority of users .

■ Reliability of starting (no load, full load). Using zero voltage sweep frequency starting mode make the starting performance is greatly improved .

■ Additional function interface, such as timing startup furnace, remote control, computer monitoring control, dual power supply ,fault self-diagnosis system and etc, to meet the requirements of modern production.

* Provide Customized Personalized Service

*Middle East Customer Customized Case

Technical requriements :

| No. | Rod Dimension | Heating weight | Time (Second ) | Power |

| 1 | Φ45*1100 | 3 | 50 | 160KW |

Scope of supply :

| No. | Name Specifications and model | Q’ty | Notes |

| 1 |

Medium-frequency power supply KGPS160KW/2.5KHZ |

1 set | Complete frequency conversion device, compensation capacitor and bus-barwire, etc |

| 2 | Furnace body 2000X1000X1250MM | 1 set | Including cylinder push, channel, waterway, etc |

| 3 |

Inductor GTRφ45 |

1 set | Three-hole sensor |