Video Link:

https://www.youtube.com/watch?v=7Ge_KjNJSiQ

https://www.youtube.com/watch?v=eyUkl64HZQY

https://www.youtube.com/watch?v=QhCqfjqooxI

https://www.youtube.com/watch?v=13QB7mDu2KE

https://www.youtube.com/watch?v=6KQZFgEN0nA

https://www.youtube.com/watch?v=Q2Ru3osLiuY

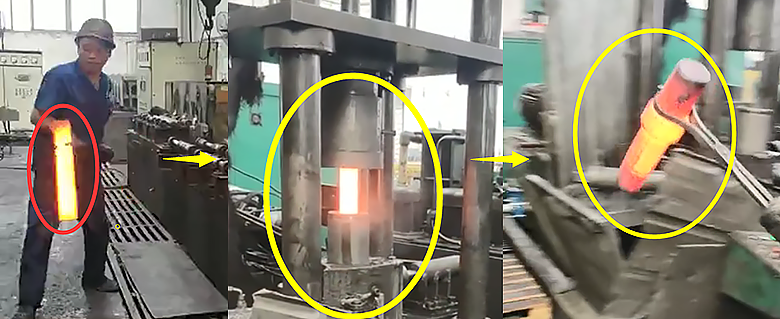

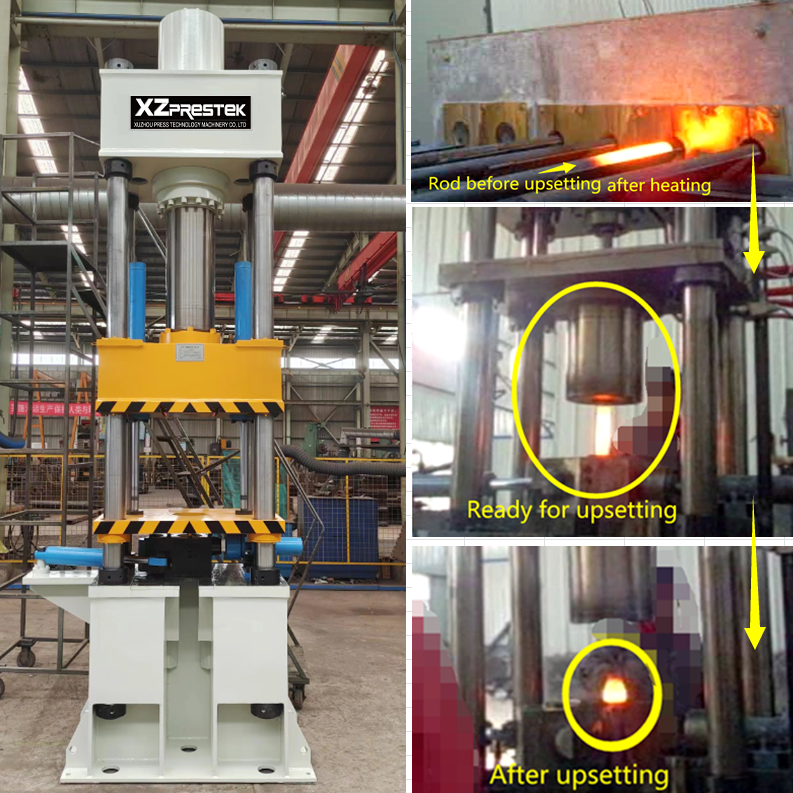

Application: Applicable to the slender bar heating end upsetting process for hot preset forming of auto half shaft flange end and multiple spline,and other preset of heating rod bar, popular in the industries of autos, tractors, ships, and etc .

Features:

■ There is a single and double stations optional , adopt hydraulic, electrical control, and centralized button control, can be realize adjustable, semi-automatic, automatic three kinds of operation models.

■ Adopts four-column single or double-action structure, with rapid clamping speed ,and clamping force adjustable.

■ Fixture adopts hydraulic driven, electric control system adopts imported PLC control, with high degree of automation, high speed of pressing , small temperature change after upsetting, which can be for rotary forging directly after heating , to improve work efficiency and save cost.

* Provide Customized Personalized Service

| Item | Unit | HUM -160/200 | HUM-200/240 | HUM -250/300 | HUM -315/355 | |

| Rated Force | KN | 2000 | 2400 | 3000 | 3650 | |

| Upsetting Force | KN | 1600 | 2000 | 2500 | 3150 | |

| Mold Clamping Force | KN | 400 | 400 | 500 | 400 | |

| Upsetting Slide Stroke | mm | 760 | 710 | 700 | 800 | |

| Mold Clamping Stroke | mm | 760 | 760 | 760 | 800 | |

| Upsetting Slide Opening Height | mm | 1650 | 1650 | 1650 | 1850 | |

| Mold Clamping Slide Opening Height | 1450 | 1450 | 1450 | 1650 | ||

| Slide Speed | Work | mm/s | 30-64 | 30-62 | 28-58 | 23-58 |

| Return | mm/s | 120 | 180 | 180 | 280 | |

| Bolster | L-R | mm | 700 | 700 | 800 | 1000 |

| F-B | mm | 700 | 800 | 800 | 920 | |

| No of Stations | Single Station | Single Station | Single Station | Single Station | ||

| Moptor Power | KW | ~40 | ~60 | ~70 | ~90 | |