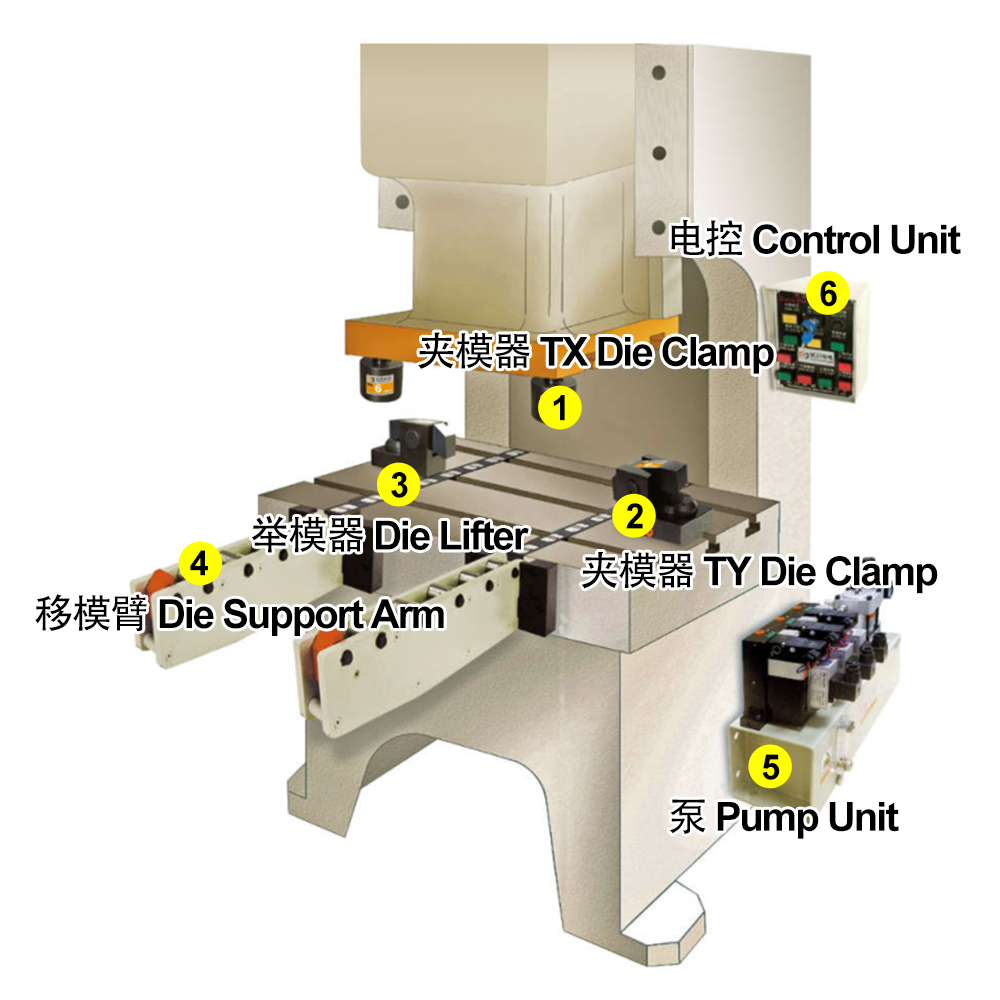

Technical Brief Introduction :

① TX Die Clamp : Clamping die to avoid manual clamping

② TY Die Clamp : Clamping die to avoid manual clamping

③ Die Lifter : Lift the die (mold) for moving in/out easily

④ Die Support Arm : Auxiliary mold moving in and out easily

⑤ Pump Unit : Power supply, air pressure turn to oil pressure

⑥ Control Unit : System control operation

QDCS---Y27K -630(2.5X1.6)—H Frame Hydraulic press 630ton

| No | Name | Model | Q’ty | Unit | Technical Parameters | Notes |

| 1 | Oil Pump System | SP6308U-3 | 1 | Set | Oil Pressure :24.5Mpa | |

| 2 | Die Clamp Upper | TX-10 | 8 | pc |

1)Clamping Force:10T 2) Full Stroke:8 mm 3) Clamping Stroke: 3mm 4) Safety Extra Stroke : 5 mm 5) Clamping Cylinder Capacity :32 cc 6) Mold Clamping Height tolerance : ±1mm |

Mold Clamping Height |

| 3 | Die Clamp Lower | TX-10 | 6 | pc | ||

| 4 |

Die Lifter (wheel roller type ) |

DL50--1600 | 4 | pc |

1) Length :1600mm 2) Roller Q'ty : 16pcs 3) Lift Cylinder :7 Pcs 4) Load Force : 3.4 ton |

What is the total weight of maximum mold ? 2-3 manual can drive 10ton moulds |

| 5 | Die Arm | 4 | Set |

1) Overall Length :1600mm 2) Maximum Load: 2.5 T |

Considering the foundation construction, what the height of the table to the ground? |

|

| 6 | Control system | 1 | pc | |||

| 7 | Auxiliary materials | 1 | pc | For connecting and installing |