Technical Brief Introduction :

1. Application :

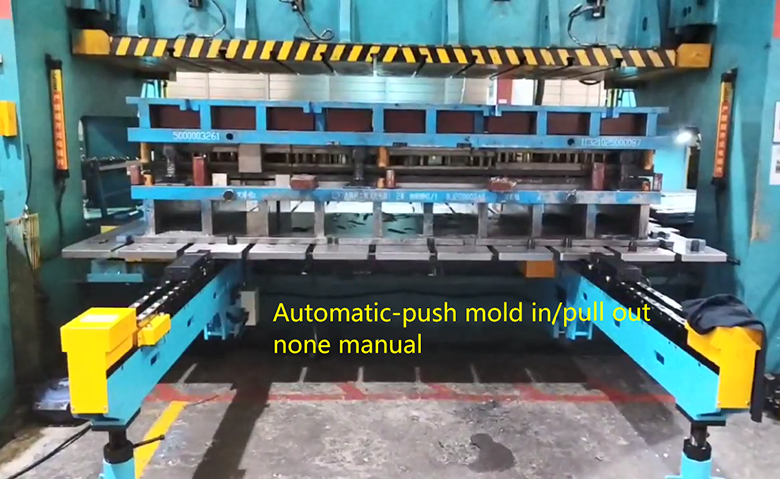

Electrical–drive Mold Change System instead of manual mold change, much improve work efficiency and labor saving, especially suitable for heavy mold replacement.

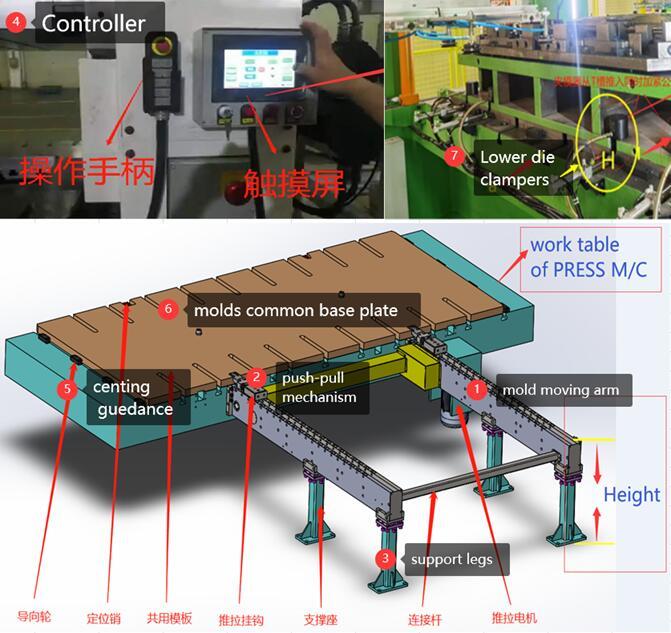

2. Constitution :

① Mold Moving arm with rollers length 2000 mm .

② Automatic Push–pull mechasnism .

③ Support legs

④ Controller

⑤ Centering guidance (rollers) system

⑥ Molds Common Base Plate

⑦ Oil Pump System

⑧ Die Clamp Upper/Lower TX-6

⑨ Die Lifter (wheel roller type )

⑩ Control system, Auxiliary material

* ASEAN (Association of Southeast Asian Nations)Customer Customized Case

SERVO 200TON AUTOMOTIVE INTERIOR HYDRAULIC PRESS

- Table size: H frame 2200 x 1800 mm

* Provide Customized Personalized Service

| No | DESCRIPTION | Q’ty | NOTES | |

| 1 |

Automatic Mold Load–Unload Unit (Mold weight≤10T ) |

① Mold Moving arm with rollers length 2000 mm . |

2 |

* Design Located in front of the 200ton Press M/C , assuming there is no extended up- platform problem with the crane lifting . * Height adjustable ±20mm . |

|

② Automatic Push– pull mechasnism . |

1 | * Motor 1.5 kw , | ||

| ③ Support legs | 4 | * Fixed , neither folded nor moveable | ||

| ④ Controller | 1 | * with variable frequency speed adjustment | ||

|

⑤ Centering guidance (rollers) system |

1 | |||

| 2 | ⑥ Molds Common Base Plate | 1 |

* Size :2000 (L) × 1600 (W)× 40 (Thick) mm |

|

| 3 | ⑦ Oil Pump System | 1 | ||

| ⑧ Die Clamp Upper/Lower TX-6 | 6 + 4 | |||

| ⑨ Die Lifter (wheel roller type ) | 4 | |||

| ⑩ Control system, Auxiliary materials | ||||

| Labour cost of installation |

Domestic installation commissioning , together with new 200ton press M/C ,and taking videos of guidance |

|||